Structure Designed for Success

At Mnemonics, Inc, we recognize the challenge that comes with the fast paced world of defense technology and have strategically organized our company into three functional divisions: Electronics Systems Division (ESD), Electronic Manufacturing Services Division (EMS), and Technical Services Division (TSD).

This approach enables us to offer specialized products and customer-aligned enterprises, ensuring that each division focuses on delivering world-class capabilities in their respective areas with in-house engineering. By adopting this structure, we provide our customers with the benefits of a streamlined, synergistic approach, resulting in high performance and a tradition of excellence.

Looking for a partner built to meet the pace and precision of modern defense? Connect with us today and discover how our strategically aligned divisions, in-house engineering, and streamlined approach can drive your project forward.

From Design to Deployment

Our in-house capabilities allow for fast turnarounds without compromising precision.

Empowering Your Competitive Edge

Stay ahead of the curve with Mnemonics’ top-notch circuit card assembly (CCA assembly), box builds, and test capabilities. Our advanced manufacturing facility is geared towards delivering results that enhance your competitive advantage. By leveraging our expertise, you can enjoy faster time to market, improved product quality, and increased profitability. We specialize in prototype, pre-production, and production fabrication, including surface mount technology (SMT), thru-hole (PTH), mixed technology assemblies, wire and cable harness assemblies, box builds, and complete system assembly.

With our technical support, turnkey and consignment options, component engineering, and materials management, we ensure your project is in capable hands from start to finish. And rest assured; we’re equipped with cutting-edge technologies such as automated optical inspection, X-ray inspection, and design for test (DFT) practices, guaranteeing optimal performance and quality.

CCA Manufacturing

Our manufacturing facility boasts three production assembly lines along with specialized equipment, offering a wide range of capabilities. We specialize in Surface Mount Technology (SMT) and Thru-Hole (PTH) component placement for CCAs. Our expertise extends to various components such as BGAs, µBGAs, FPGAs, QFPs, and QFNs. Additionally, we ensure the highest quality standards by utilizing conformal coats as required, employing dry storage, and subjecting all boards to a baking process prior to production.

Our ultimate objective is to unlock your full potential while delivering exceptional products of the utmost quality.

Mnemonics delivers what you expect from a Full Service, Turnkey Electronics Manufacturer, such as the following services and capabilities:

- Prototype, Pre-Production, and Production Fabrication

- Surface Mount Technology (SMT)

- Thru-Hole (PTH)

- Mixed Technology Assemblies

- Wire and Cable Harness Assemblies

- Box Build

- Full System Assembly

- Leaded & RoHS

- Turnkey & Consignment

- Component Engineering

- Obsolescence Management/Diminishing Material Sources

- Materials Management

- Detection/Prevention – Counterfeit Parts

- Design for Manufacturability (DFM)

- Automated Optical Inspection

- X-RAY Inspection

- Design for Test (DFT)

- ESS and Functional Testing

- Program Management

- Risk Management

Contract Electronics Manufacturing

Contract electronics manufacturing, also known as electronic contract manufacturing (ECM), refers to outsourcing the production of electronic components and products to a specialized company. Mnemonics Inc. provides this service, offering a full range of electronics manufacturing solutions, from prototype to full-scale production.

With advanced facilities and cutting-edge technologies like Surface Mount Technology (SMT) and automated optical inspection, Mnemonics handles the entire manufacturing process, ensuring high-quality, reliable electronics tailored to your needs.

This allows businesses to benefit from reduced production costs, faster time to market, and enhanced product quality without managing in-house manufacturing.

Turn Capabilities into Competitive Advantage with Mnemonics

Partnering with us gives you more than technical capability; you gain a strategic advantage at every project stage, from concept and design to manufacturing, testing, and long-term support. Our integrated structure, in-house engineering expertise, and commitment to quality ensure faster development cycles, reduced risk, and consistent performance in the most demanding environments.

Accelerated Time to Market

Our streamlined structure and in-house engineering allow us to move quickly from prototype to production, helping you deliver faster and stay ahead of the competition.

Uncompromising Quality

With rigorous testing processes, industry certifications (AS9100C, ISO 9001:2008, CMMI-3), and advanced inspection technologies, you can count on reliable, high-performance electronics every time.

Cost-Effective Solutions

From turnkey services to smart component sourcing and obsolescence management, we help you reduce costs without compromising quality.

Flexibility at Every Stage

Whether you need low-volume prototyping or full-scale production, Mnemonics adapts to your needs with turnkey and consignment options.

Expert Program Management

We manage risk, oversee every detail, and ensure your project stays on track so you can focus on your mission, not the logistics.

Confidence in Compliance

Our experience with defense, aerospace, and industrial standards means your products meet even the most demanding specifications.

Let us help you accelerate timelines, reduce risk, and deliver mission-critical performance every step of the way. Reach out to us to discover how our full-spectrum capabilities can give your team the edge where it matters most.

Your Trusted Partner Electronics Manufacturing

Choosing Mnemonics, Inc. means choosing a company with over four decades of experience delivering mission-critical electronic systems to the aerospace, defense, and industrial markets. Our structure is designed for performance, combining in-house engineering, vertically integrated services, and a deep understanding of complex electronic assemblies.

Focusing on ruggedized and high-reliability electronics, Mnemonics delivers products built to perform in the most demanding environments. Our ability to adapt quickly to evolving requirements and deliver cost-effective, on-time solutions makes us the trusted partner for some of the most advanced defense and aerospace programs.

Contact us today to learn how our experienced team, certified processes, and end-to-end capabilities can power your next project from concept to completion.

Frequently Asked Questions

What is electronics manufacturing, and why is it important?

Electronic manufacturing is the process of designing, assembling, and producing electronic components and devices essential to modern life. This comprehensive process includes several key stages: electronic design, material sourcing, assembly, testing, and final packaging. Each stage is crucial in ensuring high-quality, reliable electronics that meet industry standards and consumer needs.

Mnemonics, Inc. brings extensive expertise to every step of the electronics manufacturing process, delivering dependable and innovative solutions for a wide range of industries.

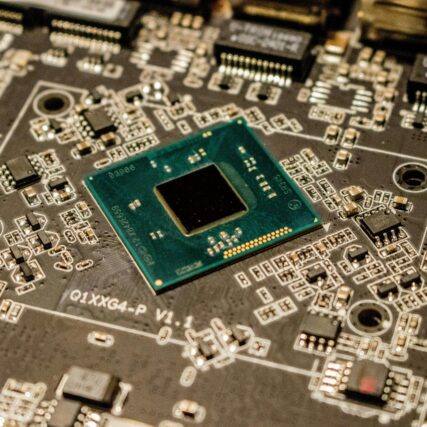

What does CCA manufacturing involve?

CCA, or Circuit Card Assembly, refers to a flat board populated with interconnected electronic components essential for various electronic devices. CCA manufacturing leverages advanced techniques, such as Surface Mount Technology (SMT) and Through-Hole Technology, to automate the assembly process efficiently and precisely. This automation ensures that Circuit Card Assemblies are built to the highest standards for functionality and durability.

Mnemonics, Inc. excels in CCA manufacturing, providing clients with expertly crafted assemblies designed to meet industry demands for quality and performance.

What are the benefits of contract electronics manufacturing?

Electronics contract manufacturers bring specialized expertise, equipment, and facilities to efficiently produce large quantities of electronic components. This streamlined process drives down material costs, minimizes waste, and enhances overall production efficiency—offering a cost-effective solution for businesses seeking quality manufacturing at scale.

Mnemonics, Inc. delivers cost-efficient electronics manufacturing services tailored to support clients’ growth and budget goals through optimized production processes.

How can contract electronics manufacturing help reduce costs?

Toggle content goes here, click edit button to change this text.

How is Mnemonics, Inc. different from other electronics manufacturing companies?

Mnemonics, Inc. stands out from other electronics manufacturing companies by combining decades of industry experience with cutting-edge technology and a commitment to precision. Our end-to-end services—from initial design and material sourcing to final assembly and rigorous quality testing—ensure a seamless manufacturing process tailored to meet each client’s specifications. Mnemonics also prioritizes innovation, efficiency, and compliance with the highest industry standards, delivering reliable solutions that align with clients’ goals for quality and cost-effectiveness.

How can I get started with Mnemonics, Inc.'s electronics manufacturing services?

To start your electronics manufacturing journey, simply contact Mnemonics, Inc. here to learn more about how our solutions can support your business.